metal detector challenge test in tablet compression|Metal detection maximum permissible rejected tablets : advice My posting main goal is to get help with the strategy to define the limit for the maximum amount of rejected tablets by the metal detector that will trigger investigations in . This article provides 10 tips for anger management, including taking a timeout, using "I" statements, physical activity and humor to diffuse tension, deep breathing exercises and . Ver mais

{plog:ftitle_list}

WEB2 de mar. de 2021 · Order food online at Pizzaro's Pizzeria & Italian, East Stroudsburg with Tripadvisor: See 129 unbiased reviews of Pizzaro's Pizzeria & Italian, ranked #4 on Tripadvisor among 100 restaurants in .

The Metal Detector Challenge Test is a critical quality control procedure used in the pharmaceutical industry, specifically for tablet compression processes. Its primary purpose is . Prepare a test set of tablets with known contamination with stainless steel or iron. wires or balls (e.g., used as sieve material for an oscillating granulator or a milling. machine). .Metal Detectors are used at the stage of tablet compression or capsule filling.These metal detectors are used to remove any metal containing tablets.To ensur. My posting main goal is to get help with the strategy to define the limit for the maximum amount of rejected tablets by the metal detector that will trigger investigations in .

Sop of challenge test of metal detector

SOP For Uphill Deduster And Metal Detector

This document provides guidance in the installation, use and maintenance of metal detectors in Pharmaceutical and Animal Health solid oral dosage form drug products and medical devices . 4.12 When all tablets are compressed & passed through Uphill Deduster & metal Detector stop the compression machine. 4.13 Check the rejection box of the metal detector .

Prepare a test set of tablets with known contamination with stainless steel or iron wires or balls (e.g., used as sieve material for an oscillating granulator or a milling machine). Pass these tablets (falling free, directed through the center of the detector area, or directed along the side of the detector area) at the different adjustable

The placement of pharmaceutical metal detection systems, sometimes called capsule metal detectors, tablet metal detectors, or API metal detectors, would heavily depend on the pharma metal detector being used and the format of the product being inspected.. METTLER TOLEDO Safeline's Tablex 2 and Tablex-PRO metal detectors should be installed after tablet presses, .

Prior to start of the tablet compression and capsule filling operation, ensure that the Blender bin containing bulk material is affixed with Approved label. . Ensure the metal detector sensitivity challenge test is performed and recorded as specified in Batch Manufacturing Record (BMR). Product interference: Certain products, such as those with high moisture content, small tablets can interfere with metal detection systems. False positives: Metal detection systems can sometimes trigger false alarms due to non-metallic objects or environmental factors. Product waste: Metal detection systems can result in the removal of otherwise safe and . 4.9 If the challenge test is passed, place a tablet/product collection container below the discharging port of the Uphill Deduster & Metal Detector. 4.10 Start the compression machine and allow tablets to pass through the Uphill Deduster & Metal Detector. 4.11 Adjust the speed of vibration & air pressure if required. 4.12 When all tablets are .

Go for autolearn and pass the tablets through the metal detector. Tablets will be collected in the rejection bottle until the system shows the successful loading of parameters. Setting for Security level of Metal Detector(User Level) Model: MetaltrapSS30 : Press the menu key on the main screen. Select the change password.

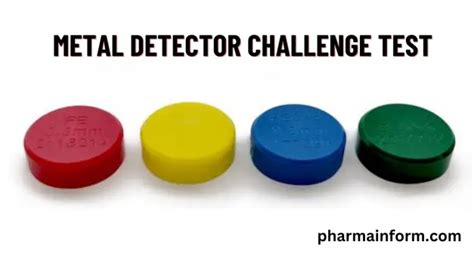

12. Metal Detector OQ should include, and is not limited to: - Alarm tests; - Test for radio frequency interference; - Challenge metal detectors used in manufacturing operations with discs/cylinders containing spherical 0.5mm ferrous, 0.5mm . What is the metal detector? Ans: A metal detector is used to detect or remove the metal pieces on tablets after their compression. Q. How to do a metal detector challenge test? Ans: It is mainly done before the start of the operation and followed by every two hours while passing one by one (SS, Fe, and Non-Fe). the challenge test is passed if . Metal detector/de-duster. During compression operation tablets are passed through a de-duster and metal detector to remove fine powders and any metal piece in tablets. . MOC of different parts. metal explanations with challenge test. bilayers tablet compression also can be add. Thanks for sharing. sir ur doing good work.. best wishes . You should qualify metal detectors used in packaging operations, for instance bulk tablet filling in such sensitivity that it can detect and isolate spherical 1.0mm ferrous, spherical 1.0mm non-ferrous and spherical 1.5mm stainless steel metal embedded in discs or cylinder carriers that are used to challenge the system.

The metal detector is equipped with a unique function that eliminates the impact of the generated noise on the metal detector. Detection sensitivity – industry-leading level Processing of metal detector’s signal for the inspection of pharmaceutical products significantly reduces the effect of the product on the detection sensitivity . Charging of product to Tablet Compression Machine’s hopper should be through a pneumatic system. 2. Discharging . Collected manually in containers. 4. Cleaning . Manual . 5. Speed/rpm. As per design . 4. Metal Detector & Deduster. High-sensitive metal detector with challenge test tablets set.Deduster & metal detector in combined model. Charging of product to Tablet Compression Machine’s hopper can be through a pneumatic system. 2: Discharging : Collected manually in containers. 3: Cleaning : Manual : 4: Speed/rpm: As per design : 5: Metal Detector & Deduster: High-sensitive metal detector with challenge test tablets set. Deduster & metal detector in combined model.

Metal detection maximum permissible rejected tablets

•Metal detector to ensure metal contamination in product is used during compression process of standby, clean and good condition of metal any abnormality observes during operation ng the same through quality notification and by performing impact assessment. SOP No. •Metal detector Challenge test is performed as per SOP No:. Operation and

#metalDetector#Packing11.2 To Confirms the Flap Operation of Metal Detector Procedure: Switch ON the Metal Detector. The Metal Detector will be in initializing mode for a period of 10 Seconds. After Initialization, in stabilized state, there should be NULL indication on the Bar Graph. The display will show for the Product Code, Sensitivity and Counts.

Explore the significance of the Metal Detector Challenge Test as a robust method for validating the effectiveness of metal detectors in tablet compression processes. Gain insights into the procedures, parameters, and acceptance criteria involved in this essential challenge test, ensuring the safety and quality of pharmaceutical products.

The placement of pharmaceutical metal detection systems, sometimes called capsule metal detectors, tablet metal detectors, or API metal detectors, would heavily depend on the pharma metal detector being used and the format of the product being inspected.. METTLER TOLEDO Safeline's Tablex 2 and Tablex-PRO metal detectors should be installed after tablet presses, .PTK PP300-DD TABLET DEDUSTER & METAL DETECTOR LAYOUT . INSIGHT PH Metal Detector Specification. Aperture Size 95mm W x 38mm H IP66, high line frame with gas strut on head and OEM Remote frame 1Mhz, VFD Display, Reject Mechanism- lift flap round, test discs 0.3mm Fe, 0.35mm Nfe & 0.5mm StSt 316 Digital control processingThe largest sample that can be utilized in our pipeline rod is 5.00mm. Pipeline rods are primarily designed to be used to validate Metal Detector Pipeline Systems between the pipe and detector aperture wall. Pharma Test Tablets. Tablet assembly is 5.0mm x 10.0mm x 25.0mm. The largest sample that can be utilized in our tablet is 3.50mm. Force feeder of the tablet compression machine contains two vital parts: Feed Peddles: It rotates continuously and ensures consistent and accurate granules feed into the die cavity in a high-speed machine. Feeder Housing: Through the feeder housing, granules for tablets from the hopper will enter into the die system. Feed Frame. Some tablet press .

Why To Perform Challenge Tests. We have to challenge the working of metal detectors to ensure that they are efficient and capable of removing any metal-containing tablets or capsules. Test Kit . During Tablet Compression: After resumption of power, challenge test for metal detector should be performed and recorded in batch record before start the compression activity then Switch “ON” the machine and Ensure that at least two round of the tablets are rejected. Ensure the group weight variation of tablets is as per limits specified in .The metal detector system in Pharmaceutical segment is widely used for detecting the external contamination in Tablets / Capsules. . The equipment is placed at the discharge of compression machine. Tablets are passed through the vertical deduster initially. The output of the deduster is feed to the metal detector unit, which checks for the . 1. Tablet Compression Machine Hopper. The tablet compression process starts from here. It is at this point that you’ll put all powder you intend to compress into tablets. Tablet press hoppers come in a wide range of shapes and designs. Whatever the shape, it should be such that the material can flow seamlessly into the tablet compression chamber.

We manufacture world-class tablet compression machines and advanced tablet coating systems that meet the diverse needs of the customers, right from R&D to manufacturing scale. Our Protab 700 is a new benchmark in high-speed tableting which simplifies all aspects of the tableting process for paramount efficiency.

4 dias atrás · Version: 923ae84656b434bb08cd80d1c643ff6a1e02f703_2024-02-26T10:36:20

metal detector challenge test in tablet compression|Metal detection maximum permissible rejected tablets